XCP Chain Lubricant

HIGH PERFORMANCE CHAIN LUBRICANT

-

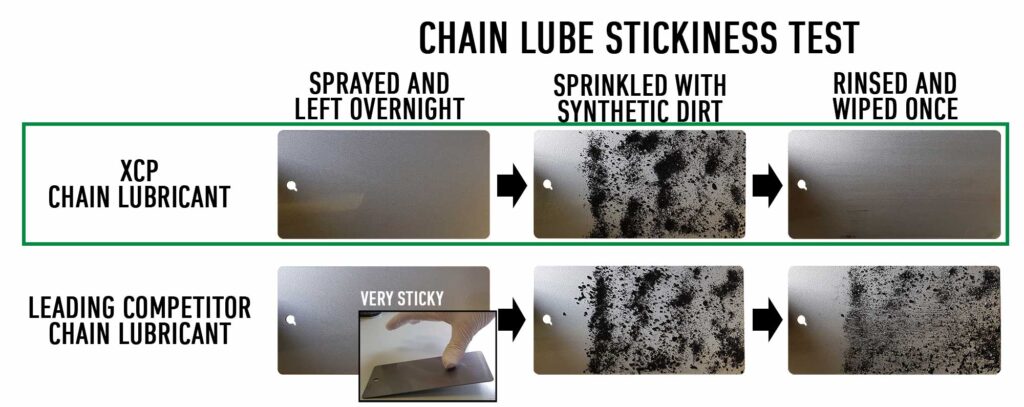

Does not attract dirt. See test.

-

Dries to a soft film that doesn’t fling.

-

Withstands extreme pressure and reduces friction.

Does not attract dirt. See test.

Dries to a soft film that doesn’t fling.

Withstands extreme pressure and reduces friction.

The lubricant quickly penetrates links and sprockets to lay down a thin, non-sticky and dirt-resistant film.

Built to withstand extreme pressure, reduce friction and minimise wear – maximising the power output of the chain.

Due to unique flow properties, an ultra-thin film is laid down on the chain, with maximum fling resistance.

Corrosion on any chain is unwanted and the XCP Chain Lubricant will help to avoid it.

XCP Chain Lubricant was originally designed for the high demanding and yet delicate printing industry, where press rollers spin at up to 15,000 rpm, with a force of up to 40,000 Newtons. In this environment, fling must be close to zero which was obtained by the strong formula, developed over 40 years ago.

A lot of chain lubricants are made extremely sticky in an attempt to stop fling. The XCP Chain Lubricant solves it differently. The lubricant penetrates the links and sprockets and then dries to an ultra-thin, non-sticky and even film. Left to dry overnight, the film will give minimal fling and will not attract dirt like other lubricants as it is not sticky.

As a result – cleaning of the chain and maintenance is much easier and power output is maximised!

Because of the lubrication formula, the XCP Chain Lubricant offers some unique properties:

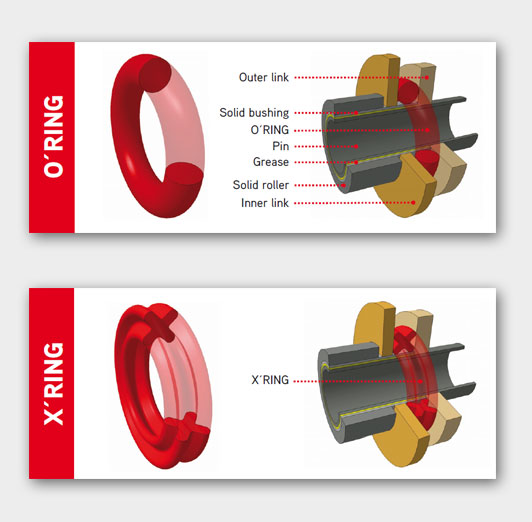

In simple terms, a modern ring chain (with an O-, X- and Z-rings) requires less upkeep and takes care of itself for the expected lifetime. The best way to maintain it is regular lubrication, cleaning and adjusting according to usage.

A modern high performance chain lubrication should not only lubricate the whole chain but:

It is essential that the chain lubricant would not attack the seal and destroy the inner lubrication. You should always choose lubricants that have been tested with O-, X- and Z-rings.

If you are not using a ring chain you should also lubricate the chain itself – XCP Chain Lubricant does an extraordinary job protecting both regular chains and ring chains.

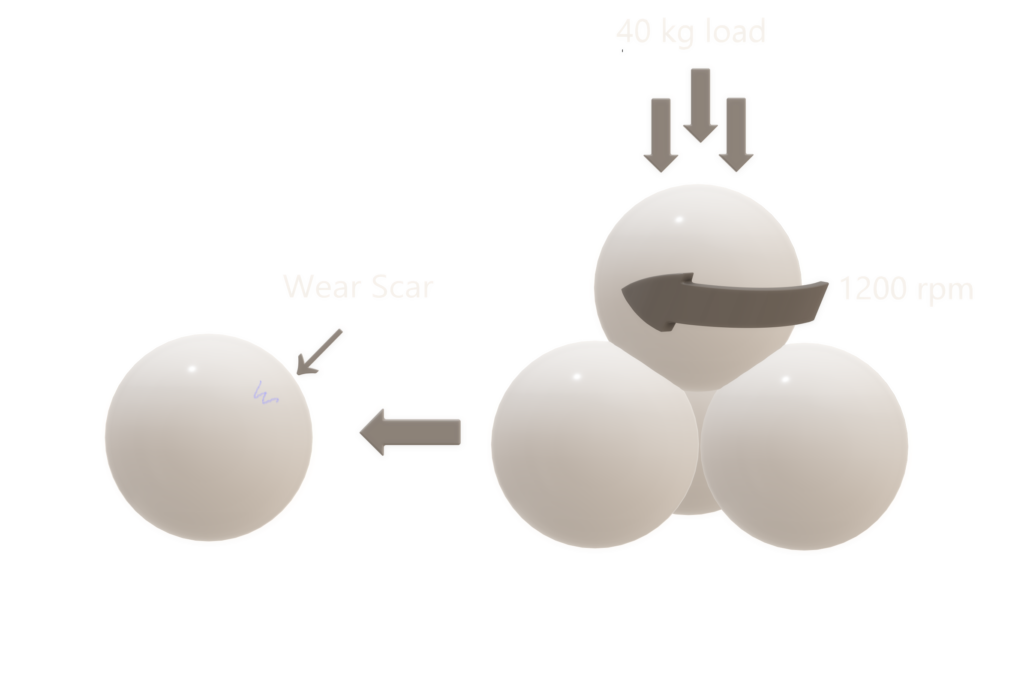

The 4-Ball Wear Scar Test (ASTM D4172) can be used to determine the relative wear preventive properties of lubricating fluids in sliding contact.

METHOD: In the 4-Ball Wear test, one steel ball spins for 1200 rotations per minute on three stationary steel balls under a 40 kg load for 60 min., per ASTM D4172.

The better the lubricant is at preventing wear, the smaller the wear scar will be on the three stationary balls. After the test, the three wear scars are measured and the average is reported.

TEST RESULTS: The test gives a wear scar of 0.54mm for the XCP Chain Lubricant.

This international standard was developed following with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations are issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ideal for use on all motor driven metal chains within different industries.

Chain lubrication has always been a hot topic within the MC industry. Correct protection of the chain will extend its lifetime and protect the sprockets.

The main problem is that fat and greasy lubricants attract dirt, which transforms the lubricant into a grinding paste. Moreover, the motorcycle gets very dirty when the chain lubricant is thrown off the chain at high speed. That makes cleaning the bike a cumbersome task.

You can avoid all the mentioned problems with the XCP Chain Lubricant’s unique properties. It can be used on All Terrain Vehicles as well.

XCP Chain Lubricant is ideal for the cycle industry.

The lubricant is so thin and non-viscous that it will cover the chain perfectly when applied correctly – a lot like other popular cycle chain lubricates. After some time, the XCP will transform into an ultra-thin coating of the chain with all the advantages.

XCP Chain Lubricant is non-sticky, reduces friction, minimises wear, resists fling and is long lasting! The product is used by many cyclists already, even by the road racing team of Andy Moore Autocentres/J.E. James Racing Team.

XCP products, including Chain Lubricant, were originally developed for industrial applications and the printing industry. This lubricant can be used at printing machinery to prolong its durability and eliminate downtime.

The Chain Lubricant can be also used on forklifts and lift chains, which need to be regularly serviced and lubricated to prevent chains from corroding and running dry.

The lubricant is a good solution for conveyor machinery, where lubrication is vital to obtain the maximum service life from a chain drive and conveyor.

Overall, XCP Chain Lubricant is designed for use on all metal motor driven chains and can solve problems in different industries.

One of the key selling points of XCP Chain Lubricant is that it leaves a thin, even and non-sticky film.

Many chain lubricants are made extremely sticky in order to stop fling. However, the XCP Chain Lubricant solves the fling problem with a new approach. The lubricant penetrates the link and sprockets and dries to an ultra thin, non-sticky film that should be left to dry overnight.

As a result – the film will give minimal fling and will not attract dirt like other lubricants. Cleaning and maintenance of the chain are much easier and power output is maximised!

Don’t let the chain lubricant act like a grinding paste! Try out the XCP Chain Lubricant, it’s a Game Changer!

To showcase it we used some steel panels that have been sprayed with XCP Chain Lubricant and a competitor chain lubricant.

We left them to dry overnight and then sprinkled the panels with synthetic dirt. After that, we rinsed the plates under the tap and wiped them once. You can see the difference between the amount of dirt that is left on the plates!

Apply the XCP Chain Lubricant sparingly and evenly to the clean chain, and ensure that excess liquid is wiped off. Ideally on a warm chain.

Due to the excellent penetration and flow properties of the XCP Chain Lubricant, be aware that a little goes a long way. Over applying will only lubricate the garage floor!

Rotate the wheel to assist flow and penetration into links and sprockets. For best results, leave overnight before use.

XCP Chain Lubricant is great at preventing wear (ASTM D4172 test results – 0.54 mm of a wear scar) and is non-sticky in comparison to competitors. The lubricant gets a lot of attraction already, but it is still a new product on the European market. See what reviewers and industrial magazines say about it!

Reviewed: XCP Chain Lubricant for more than 500 miles (800 km) ride in both wet and dry conditions.

Results: Extremely satisfied.

Read the full review here

All Year Biker is the UK’s No.1 treatment provider for professional application of corrosion prevention, dedicated to treating motorcycles to withstand all year use.

MotorCycleNews, with nearly half a billion papers sold and more than 1.5 billion readers, gives the XCP Chain Lubricant:

5 out of 5 stars.

Read the review here.

INTERESTED IN OFFERING THE BEST PROTECTION AND MAINTENANCE PRODUCTS TO YOUR CUSTOMERS?

Contact us and let us know which products you would like to sell.

We are committed to offering the best service, long-term partnerships and prices that beat the competition.