XCP Lubricate & Protect

HIGH PERFORMANCE LUBRICATION

-

Withstands extreme pressure.

-

A powerful blend of mineral and bio-based ingredients.

-

Specialist product.

-

Up to 60% reduced wear. See test.

Withstands extreme pressure.

A powerful blend of mineral and bio-based ingredients.

Specialist product.

Up to 60% reduced wear. See test.

Disperse quickly and widely across the applied surface. A thin, colourless soft coating will keep parts loose, lubricated and protected.

Withstands high pressure applications and reduces the impact of friction between moving parts.

Helps to minimise the long-term effects of wear and prolong the usability of tools and equipment.

The unique formula provides long lasting protection against moisture and corrosive elements. No corrosion or rust!

The formula of the XCP Lubricate & Protect was developed based on years of experience in industrial environments around the world.

The XCP Lubricate & Protect can extend the life of the equipment and tools, as it delivers long lasting, high performance lubrication and has some unique features.

Tests and reported service experience shows wear reduction and lubrication qualities improved by up to 60% in comparison to the leading competitor. See test.

You can apply the XCP Lubricate & Protect spray to any metal surface. It will help to maintain parts in great conditions.

Use it on joints, bearings, cables, chains, slide mechanisms, gears, pulleys, locks, wire rope, winches, cogs, bushings, cranks, axles, hydraulics, hand and power tools, and many more!

will deliver maximum performance in a wide range of applications, including high pressure and motion.

Lubrication is an important part of correct automotive maintenance, as it can prolong the usability of parts. XCP Lubricate & Protect can be used on a wide range of metal parts like joints, bearings, cables, winches, cogs, etc. The formula will keep metal parts loose and lubricated, protected against moisture and corrosive elements. It is less messy to work with and does not attract dirt as spray greases do. It can be used on ATV, motorhomes and caravans as well.

While we advise using the XCP Chain Lubricant specifically for chain lubrication, the XCP Lubricate & Protect can be used on any metal part of the motorcycle or bicycle. Try it out on joints, bearings, cables, chains, locks, gears, pegs, pivots, etc. and minimise the long-term effects of wear.

As the formula does not attract dirt like other sprays, it will make it easier to clean and maintain motorcycles and bicycles. Extra protection against rust and corrosion during all weather conditions is just another advantage!

XCP Lubricate & Protect is developed to be used on metal surfaces and can extend the life of the equipment and tools, as it delivers long lasting, high performance lubrication.

Yet, it provides protection against moisture and corrosive elements, which is especially important within the aviation and marine industries. Use this specialist’s product as a part of your maintenance routine!

XCP Lubricate & Protect can be used at home or garden, in garage and workshops, for gym equipment and snow moving equipment, plant equipment and tools. Moreover, it can be used on fishing tackle and equipment, as well as boating and water sports. The formula will keep tools and equipment in good condition with minimal maintenance. A thin, colourless soft coating will keep metal parts loose, lubricated and protected against rust and corrosion.

XCP Lubricate & Protect formula was developed based on years of experience in industrial environments around the world. It withstands high pressure applications and reduces the impact of friction between moving parts.

Therefore, it can be used in different industries like the engineering industry, mining and quarries, agricultural machinery and snow moving equipment.

Try it on joints, bearings, cables, chains, slide mechanisms, gears, pulleys, locks, wire rope, winches, cogs, bushings, cranks, axles, hydraulics, hand and power tools, and many more!

This test (ASTM D4172) covers a procedure for making a preliminary evaluation of the anti-wear properties of fluid lubricants in sliding contact by means of the Four-Ball Wear Test Machine.

METHOD: Three diameter steel balls are clamped together and covered with the lubricant. A fourth steel ball is pressed with a force of 40 kg into the cavity. The temperature of the test lubricant is regulated at 75°C and then the top ball is rotated at 1200 rpm for 60 min.

The better the lubricant is at preventing wear, the smaller the wear scar will be on the three stationary balls.

Results:

Test results and service experience show wear reduction and lubrication qualities improved by up to 60% when compared to the market leader.

Try out the XCP Lubricate & Protect!

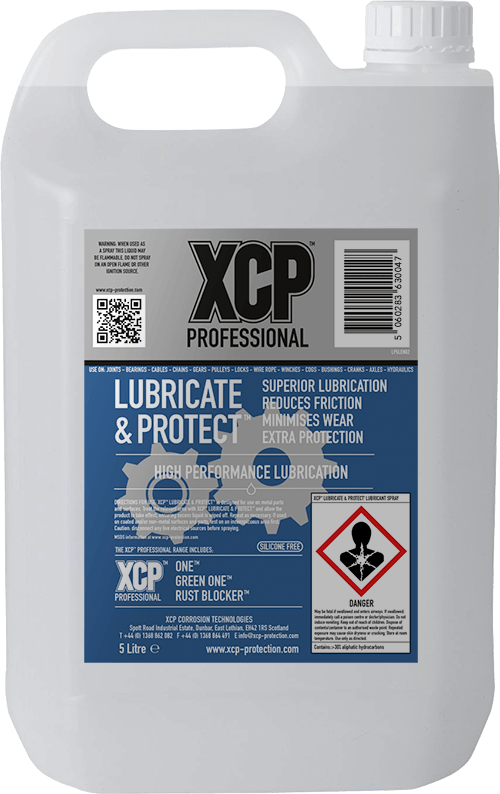

XCP Lubricate & Protect is designed for use with metal parts or surfaces. For retail markets and individuals, the Lubricate & Protect will be most useful in aerosol or trigger spray cans. However, it is also available in 5 liter dunks to be used in production and industrial environments.

To ensure great results, treat the relevant part with XCP Lubricate & Protect and allow the product to take effect. Check that the excess liquid is wiped off. You can repeat the application if necessary.

If used on coated and/or non-metal surfaces and parts, test on an inconspicuous area first. Caution: disconnect any live electrical sources before spraying.

XCP Lubricate & Protect can improve wear reduction and lubrication qualities up to 60% when compared to the market leader (ASTM D4172 test results – 0.55 mm wear scar). But you don’t have to take our word for it, try it yourself!

INTERESTED IN OFFERING THE BEST PROTECTION AND MAINTENANCE PRODUCTS TO YOUR CUSTOMERS?

Contact us and let us know which products you would like to sell.

We are committed to offering the best service, long-term partnerships and prices that beat the competition.